The following technology platforms are employed for our assay services or products:

Luminex Bead-Based Multiplex Assay

Our multiplexing immunoassays with bead suspensions are

based on xMAP (Multiple- Analyte

Profile) technology developed by Luminex Corp.

Luminex bead-based multiplexing sandwich

immunoassays for protein biomarkers employ a suspension of microsphere sets in

a 96-well microplate where each bead set represents an individual immunoassay.

The microspheres are 6.5-µm paramagnetic beads functionalized with carboxyl groups on the bead

surface for covalent attachment of capture antibodies. The beads are internally

encoded by fluorescent dyes and individually addressed to a specific assay in

the multiplexed tests. This technology uses a proprietary dying process to

create up to 500 unique dye mixtures which are used to identify an individual

bead. The fluorophore-coded beads function as bar codes for individual analyte. Each bead set can be coated with a capture

antibody specific to one analyte. During a bead-based

sandwich immunoassay, captured analyte on the bead

surface is bound by a biotinylated detection antibody and streptavidin-phycoerythrin (S-PE). Multiple analytes in a single

aliquot of serum, plasma, cell culture supernatant, cell lysate and tissue

extract, etc. are determined quantitatively and simultaneously with a Luminex bead reader. Within the bead reader, one laser

excites the beads’ internal dyes, which identify each bead set by its fluorescent

color code, while a second laser excites the reporter dye (PE) captured during

the assay. Tens to hundreds of readings are made for each bead set. The bead reader

classifies each bead according to its predefined map region by means of digital

signal processing. The magnitude of the reporter-derived signal is in

direct proportion to the amount of analyte bound. Analyte concentrations

of the multiplex immnuassays are typically determined

by 5-parametere logistic regression algorithm with analysis of the median

fluorescence intensity readings of each 8-point calibrator curve.

High-Sensitivity MSD-ECL Multiplex Assay

In addition to

conventional Luminex bead-based multiplex assays and ELISAs as a broad initial

analysis for biomarker profiling, our high-sensitivity singleplex

and multiplex assays are established upon Meso Scale Diagnostics-

electrochemiluminescence (MSD-ECL) technology platform to detect low-abundance

biomarkers difficult to measure with conventional assays. Electrochemiluminescent

labels generate light when stimulated by electricity in the appropriate

chemical environment. This reaction is incorporated into our immunoassays to

provide the light signal used to measure important proteins and other

biomedical molecules. Multiple excitation cycles can amplify signals

to enhance light levels. The stimulation method (electricity) is decoupled from

the signal (light) allowing only labels near the electrode surface to be

detected. MSD-ECL assay sensitivity increases over conventional assays result from

ECL signal amplification and low background (high ratio of signal-to-noise). Additionally,

the wider dynamic range (3-4+logs) of MSD-ECL detection systems can be achieved so that high and low

expression levels can be measured without multiple sample dilutions.

How does

electrochemiluminescence work?

Electrochemiluminescence Implementation

1. High binding carbon electrodes in the bottom of MULTI-ARRAY and MULTI-SPOT microplates

allow for easy attachment of biological reagents (10X greater binding capacity than polystyrene).

2. MSD assays use electrochemiluminescent labels that are conjugated to detection antibodies.

The labels are called SULFO-TAG, and allow for ultra-sensitive detection

3. Electricity is applied to the plate electrodes by an MSD instrument leading to light emission

by SULFO-TAG labels. Light intensity is then measured to quantify analytes in the sample.

Electrochemiluminescence Advantage

1. High sensitivity: Multiple excitation cycles can amplify signals to enhance light levels.

2. Broad dynamic range: The wide dynamic range of MSD-ECL detection systems means high and

low expression levels can be measured without multiple sample dilutions.

3. Low background: The stimulation method (electricity) is decoupled from the signal (light)

allowing only labels near the electrode surface to be detected.

4. Reduced assay matrix effects: Higher sample dilution factors are applied

for MSD-ECL system than conventional assays..

5. Great flexibility:

Labels are stable, non-radioactive, non-fluorescent, and conveniently

conjugated to biological molecules. In particular, fluorophore labeled cell samples

(cell lysate and culture supernatants, etc.) can be analyzed with MSD-ECL

detection system at high sensitivity.

6. Unsurpassed performance and quality: Electrochemiluminescence

is a highly successful detection system that achieves clinical quality data in a variety of sample

types, including cell supernatant, serum, plasma, and whole blood.

Ultra-Sensitive

Bead-Based Assay

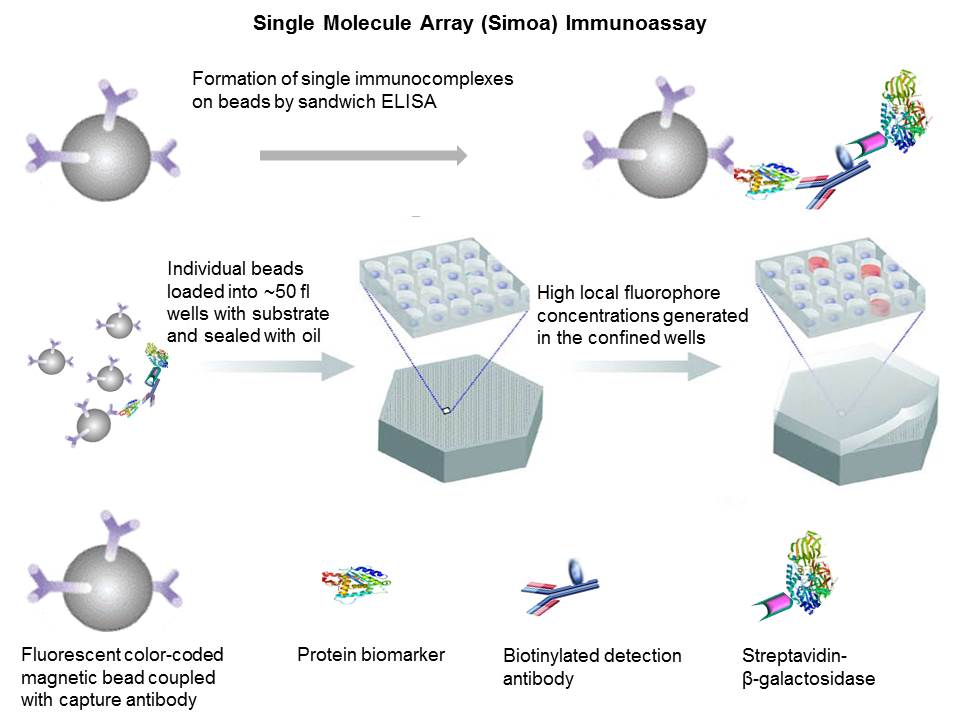

Our ultra-sensitive immunoassays are established upon Quanterix’s Simoa (Single Molecule Array) technology to

detect low abundance protein targets.

During

ultra-sensitive single molecule array (Simoa)

sandwich immunoassays, fluorescently distinct paramagnetic beads (2.7 µm

diameter) are coupled with a capture antibody. Conventional bead-based sandwich

immunoassay approach is applied but single immunocomplexes

labeled with enzyme (streptavidin-β-galactosidase) are formed on the bead surface.

When samples containing extremely low concentrations of analytes

are tested, the ratio of analyte molecules (and the

resulting immunocomplexes) to beads is small (<1) and

the percentage of beads that contain a labeled immunocomplex

follows a Poisson distribution - beads carry either a single immunocomplex or none. It is impossible to detect these low

numbers of enzyme labels using conventional detection technology, because the

fluorophores generated by each enzyme diffuse into a large assay volume

(typically greater than 0.1 mL). It takes hundreds of thousands of enzyme

labels to generate a fluorescence signal above background.

The

very low concentrations of enzyme labels on the bead surface can be detected by

loading beads (diameters of 2.7 µm) into an array of 216,000 wells (diameters

of 4.5 μm and depths of 3.25 μm)

and confining the fluorophores generated by individual enzymes to extremely

small volumes (~50 femtoliter). Beads are sealed with

oil to ensure only one bead in a well. Beads carrying a single enzyme-labeled immunocomplex generate a high local concentration of

fluorophores in the confined well. By acquiring time-lapsed fluorescence images

of the array using standard microscopic optics, it is possible to differentiate

beads associated with a single enzyme molecule (“on” well) from those not

associated with an enzyme molecule (“off” well). At low concentrations of

proteins, when the ratio of enzyme labels to beads is less than ∼1.2, beads carry either zero or low numbers of

enzymes, and protein concentration is quantified by counting the presence of

“on” or “off” beads (digital regime). At higher protein concentrations, each

bead typically carries multiple enzyme labels, and the average number of enzyme

labels present on each bead is quantified from a measure of the average fluorescence

intensity (analog regime). Both the digital and analog concentration ranges are

quantified by a common unit, namely, average number of enzyme labels per bead

(AEB). By combining digital and analog mode for fluorescence measurement of singulated beads, a linear dynamic range of over 6 orders

of magnitude to enzyme label can be achieved.

In

ultra-sensitive single molecule array (Simoa)

multiplex sandwich assays, different capture antibodies are coupled with

fluorescently distinct paramagnetic beads. Multiple analytes

in a single aliquot of serum, plasma, cell culture supernatant, cell lysate and

tissue extract are determined quantitatively and simultaneously with Quanterix’s HD-1 Simoa

Analyzer.

Since Simoa

platform enables low analyte concentrations to be

determined digitally rather than by analogue signals, it is termed a digital

immunoassay. The digital nature

of the Simoa technology allows an average of 1000×

sensitivity increase over conventional assays with CVs <10%. This

ultra-sensitivity assay platform can be completely automated with multiplexing

and custom assay capability.

Microplate-Based

Sandwich ELISA

Our conventional microplate-based immunoassay is based on a

solid phase sandwich enzyme linked immunoassay (ELISA) method. Samples,

calibrators and controls are added to the wells coated with an antibody specific

to a target. After incubation step, the target in the samples binds to the

capture antibody on the plate well. After wash step using an ELISA Plate

Washer, anti-target detection antibody conjugated with horse radish peroxidase

(HRP) is incubated in wells and binds to the target. Unbound target and HRP conjugate

are washed off by wash buffer. Upon the addition of the substrate, the

intensity of color with an ELISA plate reader is proportional to the

concentration of target in the samples. Analyte

concentrations are typically determined by 4-parametere logistic regression

algorithm with analysis of the median optical density readings of protein

standard curve.

Positive and negative controls on a plate allow for assay

quality assurance. The tests are end-point measurements.

Microplate-Based

Competitive ELISA

Another conventional microplate-based immunoassay is based

on a solid phase competitive enzyme linked immunoassays. A primary antibody is

captured by an secondary antibody coated on a

microplate. A constant concentration of biotinylated target (tracer) and varying

concentrations of unlabeled target in samples compete for binding specifically

to the primary antibody. Therefore, the concentration of tracer-bound primary antibody

is inversely proportional to the target concentrations in samples. Captured

biotinylated tracer is subsequently bound by streptavidin-conjugated

horseradish peroxidase (HRP). After washing away the unbound components, TMB is

added as a substrate for the HRP. Finally, the enzymatic reaction is terminated

by adding an acidic stop solution. The intensity of color with an ELISA plate

reader is inversely proportional to the concentration of target in the samples.

Analyte concentrations are typically determined by 4-parametere

logistic regression algorithm with analysis of the median optical density

readings of protein standard curve. Positive and negative controls on a plate

allow for assay quality assurance. The tests are end-point measurements.

Endotoxin/LPS

Measurement

Our Endotoxin/LPS test is a quantitative, kinetic assay for

the detection of Gram negative bacterial Endotoxin in a variety of samples

including serum and plasma.

A sample is mixed with the reconstituted Limulus Amebocyte Lysate (LAL) reagent, placed in the photometer or

96-well microplate and automatically monitored over time for the appearance of

turbidity. The time required before the appearance of turbidity (Reaction Time)

is inversely proportional to the amount of endotoxin present. That is, in the

presence of a large amount of endotoxin the reaction occurs rapidly; in the

presence of a smaller amount of endotoxin the reaction time is increased. The

concentration of endotoxin in unknown samples can be calculated from a standard

curve.

|

| Proenzyme |

|

Coagulase |

|

| Coagulogen |

|

Coagulin |

Gram negative

bacterial Endotoxin catalyzes the activation of a proenzyme in the LAL. The

initial rate of activation is determined by the concentration of Endotoxin

present. The activated enzyme (Coagulase) hydrolyzes specific bonds within a

clotting protein (Coagulogen) also present in LAL.

Once hydrolyzed, the resultant coagulin

self-associates and forms a gelatinous clot. The turbidimetric

Endotoxin/LPS assay measures the increase in turbidity (optical density) that

precedes the formation of the gel clot.

How is the LAL-Based Endotoxin/LPS testing

performed for serum/plasma?

We have built up

extensive experiences in performing Endotoxin/LPS testing for serum/plasma

samples. Preliminary sample preparation is required for serum and plasma. If

testing plasma, we use “platelet rich plasma” obtained from whole blood by

centrifuging at low speeds to remove the white and red blood cells. Serum

samples, whole blood processed to remove fibrogens,

coagulants, whole blood cells, etc., can also be tested in the same manner as

plasma.

How does Olink platform work?

The unique technology behind the high-thorughput Olink multiplex assay platforms,

Proximity Extension Assay (PEA) technology, is an innovative dual recognition, DNA-coupled methodology providing exceptional readout specificity.

PEA enables high multiplex, rapid throughput biomarker analysis without compromising on data quality.

Antibody pairs labelled with DNA oligonucleotides bind target antigen in solution, allowing hybridization and extension by DNA polymerase.

This newly created piece of DNA barcode is amplified by standard PCR before transfer to an integrated microfluidic chip (IFC),

which is loaded into the instrument for qPCR and data readout.